Matthew Leitch, educator, consultant, researcher

Real Economics and sustainability

Psychology and science generally

OTHER MATERIALWorking In Uncertainty

The Triad approach to cleaning up hazardous waste sites

Contents |

Imagine you are in your kitchen and accidentally spill a spoonful of instant coffee granules onto the worktop. You can see them easily and clean them up, looking carefully to make sure you have completed the job. That's what Triad tries to do on a larger scale but one of the greatest challenges is that, unlike coffee on your kitchen worktop, hazardous waste is often invisible to the naked eye. It may be below ground, mixed with liquids or earth, colourless, or just present in tiny but deadly quantities. Rarely is it evenly spread across a site that needs to be cleaned up.

Triad deals with the fact that, at the start of a clean-up project, it is often uncertain which contaminants are present, where they are, how they are moving (if at all), or what damage they may be doing. Nevertheless, despite these fundamental uncertainties, an important project must be planned and managed according to the laws of the United States of America (where Triad has been developed by the Environmental Protection Agency). Money and lives are at stake.

In the past these uncertainties have proved a huge challenge. Samples would be taken across a site and sent away to a laboratory for testing. Weeks, sometimes even months later the results would come back. These results had the accuracy and rigour suitable for a decision to start a clean-up project, or a decision to declare a project completed, but they were often too slow and expensive to guide the cleaning work itself. Worse, because waste tends not to be evenly spread over a site, it was all too easy for a sample plan to miss bad patches on the site. Without a detailed understanding of exactly where on a site cleaning was needed there was pressure to clean it all, which was expensive and also could involve disturbing land unnecessarily.

Over the years, testing techniques have been developed that provide more rapid results. Some can be carried out in a mobile laboratory located near the site. Some can be carried out on site, perhaps even giving instant results. Those results do not need to be as accurate as the laboratory tests if their speed and low cost means they can gather a lot of information quickly, enabling bad patches to be found more reliably.

However, making good use of these techniques requires a management approach that supports adaptive testing and work. Its no good if the management approach fixes the work plan first, or fails to adapt testing to results so far, or fails to adapt cleaning work to use the latest test results.

The Triad approach

Enter the Triad approach. Its three components are:

Systematic Planning: This typically involves identifying key decisions to be made and developing a conceptual site model to support decision making. Uncertainty around the decisions is considered and ideas for resolving the uncertainty are developed. The conceptual site model clarifies where more information would help.

Dynamic Work Strategies: These are plans for work that cover site characterization, remediation, and monitoring and are written (usually by stating decision logic) so that the actual work done will change appropriately as information comes in from real-time measurement. As that information comes in decisions will be made about how to resolve the remaining uncertainties and clean up the site.

Real-time Measurement Technologies: These are measurement techniques that give results quickly enough to influence the progress of further data collection and cleaning.

Underpinning these is the Conceptual Site Model, which is where knowledge about the site is brought together and used to resolve the major uncertainties remaining in the project, supporting decisions.

An illustration of Triad in practice

The EPA has documented in detail a number of cases where Triad has been applied and these help to make clear how the decision uncertainty focused Triad approach works. One of these concerns fuel waste apparently leaking from a site containing an old landfill site and an even older factory for making gas out of coal. This waste appeared to be seeping into the nearby Cache La Poudre River in Colorado.

In this project the major uncertainties and decisions clarified during the project included:

Is the coal tar contamination found in the river the result of waste leaking from the site and if so where exactly is it coming from?

If the waste is moving from the site to the river, how is it doing that? What is its route? Is there a place where the waste can be intercepted and removed?

How much work is necessary for the landfill site?

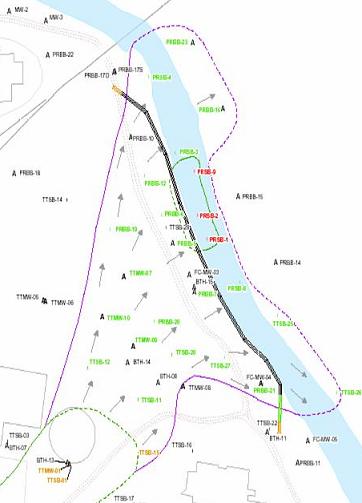

At first it was difficult to find how the waste might be reaching the river but 'fingerprinting' the waste in the river and matching it to waste on the site showed that the old gas plant was the likely source, not the landfill. An adaptive pattern of testing using several different techniques showed that the heavier coal tar was not simply flowing downhill or moving along with water. Instead, it was flowing through underground cracks in the bedrock and these were the route to the river.

The resulting plans for mitigation included work at the site to remove the source of the contamination and a huge plastic sheet buried in the ground between the river and the site with pumps along it to suck up the waste and remove it before it reaches the river.

The project team estimated a cost saving of around 30% during the site characterization phase of the work from using Triad instead of a typical conventional approach, but this is slightly misleading because using Triad a lot more data were gathered and decision making was done with more confidence. In short, the costs were less and they achieved more.

Applying Triad ideas to other projects

If you want to know more about Triad there is an extensive website with a lot of detail, and the case studies. Much of this is in rather technical language and focused on cleaning up hazardous waste sites, as you would expect.

However, the ideas underlying Triad can be applied to a much wider variety of projects. Many projects/programmes involve a 'space' with problems or opportunities unevenly distributed in a way that is not known initially but can be discovered by testing and by starting work. The nature of those problems or opportunities may also be uncertain at the outset, along with the best approach to dealing with them.

For example, how about projects to improve education in a county, or promote a range of products, or reduce manufacturing lead time, or reduce billing errors? In each case there's a 'space' (i.e. the schools and pupils, the products and customer groups and channels, the manufacturing steps and products, the billing steps and types) and we don't know in advance what will work or how well.

Common sense? Yes, it is. But as the EPA found, common sense isn't necessarily what organizations apply so it can take some effort to get back to the conceptual simplicity of cleaning up coffee granules from a kitchen worktop. If an organization has one of these projects:

Does it clarify its major uncertainties and decisions from the outset and throughout?

Does it plan to gather and use information as it goes to modify its work plan according to a sensible decision logic?

Are its plans written in such a way that they accommodate responses to new information?

Does this also apply to the plans for gaining information?

Does it pull together its information into an up-to-date representation of its understanding of the 'space' the project is working in, with consequent effects on decisions?

| Working In Uncertainty observations |

Even though this seems like common sense the cost savings in comparison with the way cleanup projects were done before are impressive. The careful attention to detail in measurement is inspiring too. Most organizations set up systems for data collection and then they just continue to gather the same data regularly. The Triad approach is very different. The data gathering is directed at particular uncertainties around particular decisions and even the data gathering itself is adaptive, with data gathering plans responding to new discoveries according to a clear and controlled logic. |

|---|

(Source of information: The Triad Resource Center website. Many thanks to Deana Crumbling of EPA for providing many great photographs, only a few of which can fit on this page.)

Made in England